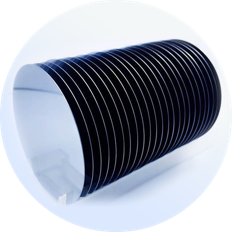

YH2M16B high precision vertical double side lapping (polishing) machine

Applicable occasions: high precision double-sided grinding and polishing.

Keywords

Precision grinding, intelligent manufacturing technology, integrated solutions

Classification

Typical Machining Parts

Typical Machining Parts

|

|

|

| Sapphire | Silicon Carbide | Ceramics |

Equipment Highlights

Equipment Highlights

(1) Unique upper plate floating fixed plate processing technology: high-precision double-sided grinding can be realized.

(2) Hydrostatic bearing support technology: to ensure extremely high bottom plate end face runout and support rigidity, to achieve high product requirements.

(3) The upper disc is equipped with a real-time online measurement system: it can detect the thickness of the ground product in real time.

(4) upper plate steel wire suspension balance structure: can realize the upper plate adaptive floating at the same time with damping function.

(5) The lower disc has high precision and high stability: the oil pressure of the outer gear ring rises and falls, and the lower disc remains fixed.

(6) Precision servo proportional valve: the upper plate is pressurized, and the pressure is accurately controllable.

Technical parameters

Technical parameters

|

Project |

Parameters |

|

Maximum size of machined workpiece |

Diagonal or round diameter of rectangular part 335mm |

|

Minimum thickness of machined workpiece |

0.2mm |

|

Size of upper and lower polishing discs (outer diameter×inner diameter×thickness) |

φ1155 × 369 φ × 50mm |

|

Maximum processing pressure |

788 kg |

|

Upper disc speed |

1-30rpm (stepless speed regulation) |

|

Lower disc speed |

1-70rpm (stepless speed regulation) |

|

Sun wheel speed |

1-45rpm (stepless speed regulation) |

|

Outer gear ring speed |

1-40rpm (stepless speed regulation) |

|

Number of Star Wheels |

5 |

|

Overall dimension (length×width×height) |

1950 × 1700 × 3200 |

|

Weight of whole machine |

About 7000 kg |

Previous article

Previous article

recommend products