YHJMKG2880

High precision CNC compound vertical grinding machine

The target market of this machine tool is the domestic equipment manufacturing industry, machinery processing industry, high-precision processing industry and other products with high precision and surface quality requirements, which can realize one-time clamping processing of the inner and outer contours, inner holes, outer circles, end faces, etc. of discs, rings and sets. The machining accuracy grade is IT3 ~ IT2 grade; the surface quality is controlled at Ra≤ 0.2; the shape and position error is controlled at ≤ 0.002.

Keywords

Precision grinding, intelligent manufacturing technology, integrated solutions

Classification

Typical Machining Parts

Typical Machining Parts

|

|

|

|

|

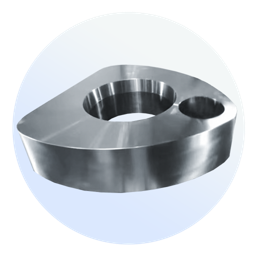

| Bearing seat | wind power gear | triangular rotor | |

Equipment Highlights

Equipment Highlights

1. X-axis, C- axis, Z-axis and B- axis can realize two-axis to four-axis linkage, and can realize the processing of inner and outer contours, conical surfaces, end surfaces, etc. of workpieces.

2. Equipped with 3 synchronous built-in motorized spindles (SP1, SP2, SP3), the station can be converted, the grinding head covers a wide range of rotation speed and rigidity, and effectively improves the processing efficiency and manufacturability.

3. The B- axis can realize high-precision and arbitrary angle positioning with repeated positioning accuracy of 2.5 ", and can realize arbitrary cone surface processing, thus avoiding the deficiency of linkage interpolation processing cone surface and reducing grinding wheel loss.

4. The X-axis and C- axis are hydrostatic methods, which can effectively solve the unstable transmission of traditional guide rails and the phenomenon of low-speed crawling caused by friction while ensuring high precision and high rigidity (the friction coefficient of hydrostatic guide rails is only about 0.005, and that of linear guide rails is generally 0.15).

5. The X-axis adopts direct drive motor without reverse clearance, which can completely solve the problems such as over-quadrant protrusion.

6. SP1, SP2 and SP3 are equipped with online dynamic balancing and AE devices to effectively solve the grinding vibration and abnormal collision caused by unbalanced grinding wheel, and improve the grinding surface quality and the safety of machine tools.

7. The B- axis is equipped with a clamping system, and the rated locking torque is as high as 2900N.m to ensure the rigidity of the grinding wheel when grinding at a fixed angle.

8. On-line automatic measurement function, which can realize automatic on-line measurement and automatic tool alignment; the probe calibration device is close to the detection position, and the measurement accuracy is high.

9. Equipped with diamond roller dressing and diamond pen dressing, two sand dressing methods can realize grinding wheel plane and surface dressing.

10. Human-computer interaction software with 3D simulation and full-function CNC program package, including functions such as end face grinding, inner circle (inner contour) grinding, outer circle (outer contour) grinding, grinding wheel modification, online measurement and calibration.

Technical parameters

Technical parameters

|

Project |

Parameters |

|

Table size |

Ф800 mm |

|

Maximum swing diameter |

Ф1000mm |

|

Minimum grinding inner diameter |

Ф28 mm |

|

Max. grinding height |

650 mm |

|

Maximum load of workbench |

1500 Kg |

|

Table speed (stepless) |

0.01-100 rpm |

|

Maximum spindle speed and interface (internal and external grinding head) |

8000rpm、 HSK63-C(18000rpm optional accessory) |

|

Maximum spindle speed and interface (surface grinding head) |

4500rpm、N56 |

|

Grinding wheel diameter (inner and outer grinding head) |

Ф25~Ф300mm |

|

Grinding wheel diameter (surface grinding head) |

F400 |

|

Spindle power (inner and outer cylindrical grinding head) |

32kW |

|

Spindle power (surface grinding head) |

37kW |

|

Spindle runout |

Radial and end face ≤ 0.001 |

|

Project |

Parameters |

|

Table runout |

Radial and end face ≤ 0.001 |

|

X-axis (lateral movement) |

1700 mm |

|

Z-axis (vertical movement) |

1340 mm |

|

B- axis (rotation of grinding wheel carrier) |

0~285° |

|

X-axis moving speed (continuously variable speed) |

0.010~10 m/min |

|

Z-axis moving speed (continuously variable speed) |

0.010~8 m/min |

|

X and Z axis positioning accuracy and Repeated positioning accuracy |

0.003mm, 0.002mm |

|

C- axis positioning accuracy and repeated positioning accuracy |

3 ″, 1.5 ″ |

|

B- axis positioning accuracy and repeated positioning accuracy |

5 ″, 2.5 ″ |

|

The grinding head moves in the X-axis direction. Parallelism of rotating table surface |

≤ 0.006mm/500mm |

|

The grinding head moves along the Z-axis direction. Verticality of rotary table surface |

≤ 0.003mm/500mm |

High Precision CNC Vertical Universal Grinding Machine Series

| Sr. | Model | Workstation diameter(mm) | Max. rotation diameter(mm) | Max. workpiece height (mm) | Max. workpiece weight(kg) |

| 1 | YHJMKG2835 | ф350 | ф3500 | 400 | 800 |

| 2 | YHJMKG2860 | ф3600 | ф3750 | 500 | 1000 |

| 3 | YHJMKG2880 | ф3800 | ф31000 | 650 | 1500 |

| 4 | YHJMKG28100 | ф31000 | ф31200 | 650 | 2000 |

| 5 | YHJMKG28125 | ф31250 | ф31500 | 650 | 3000 |

| 6 | YHJMKG28160 | ф31600 | ф31850 | 850 | 5000 |

| 7 | YHJMKG28200 | ф32000 | ф32300 | 1050 | 5000 |

Previous article

Next article

Previous article

Next article

recommend products