YHDM580B/5 High Precision Vertical Double Face Grinding Machine

This machine can process all kinds of shaped and round metal, non-metallic thin parts (bearings, valves, aluminum alloy plates, seals, oil pump blades, piston rings, etc.) on the two parallel end face of high-efficiency precision grinding.

Keywords

Precision grinding, intelligent manufacturing technology, integrated solutions

Classification

Typical Machining Parts

Typical Machining Parts

|

|

|

|

|||||

| even bar | inner and outer rotor | magnetic material | |||||

Processing mode

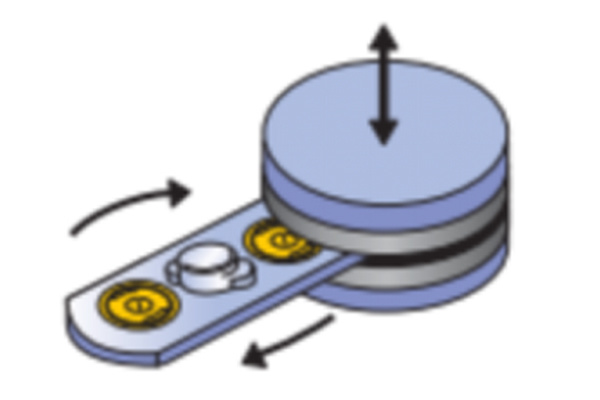

Planetary Grinding (XX)

Suitable for thick workpieces, workpieces with verticality requirements, large removal

Equipment Highlights

Equipment Highlights

● The fuselage adopts casting box structure, with good shock absorption, rigidity and reliable thermal stability.

● The coolant is filtered by magnetic separation and paper tape filtration, and the cooling machine is recycled after temperature control.

The hinged disc feeding mechanism is adopted, which is flexible to open and convenient to replace and trim the grinding wheel.

● Equipped with automatic grinding wheel dressing device, convenient and fast, to ensure the quality of grinding wheel correction.

● The feed axis is driven by a servo motor, with stable movement, accurate positioning and convenient adjustment.

Technical parameters

Technical parameters

|

Item/Product Model |

Unit |

YHDM580B/5 |

|

Machining workpiece diameter |

mm |

Φ20-Φ240 |

|

Machined workpiece thickness |

mm |

8-40 |

|

Grinding wheel size |

mm |

Φ585xΦ195 |

|

Grinding head motor |

kw |

30kw x 2 |

|

Grinding head speed |

Rmp |

150-950 |

|

Feed tray motor power |

kw |

1.5 x 3 |

|

Whole machine quality |

kg |

9000 |

|

Overall dimensions of machine tool (length x width x height (L x W x H) |

mm |

2550x2300x2880 |

Previous article

Previous article

recommend products