YHM7418B CNC double-station single-side grinding machine

This machine is suitable for single-sided high-precision grinding of metal parts, as well as single-sided thinning or polishing of thin sheet parts made of non-metallic hard and brittle materials such as mobile phone glass, ceramics, and wafers.

Keywords

Precision grinding, intelligent manufacturing technology, integrated solutions

Classification

Typical Machining Parts

Typical Machining Parts

|

|

|

|

|

| Rotor | Mobile phone glass | large bearing | Gear |

Processing mode

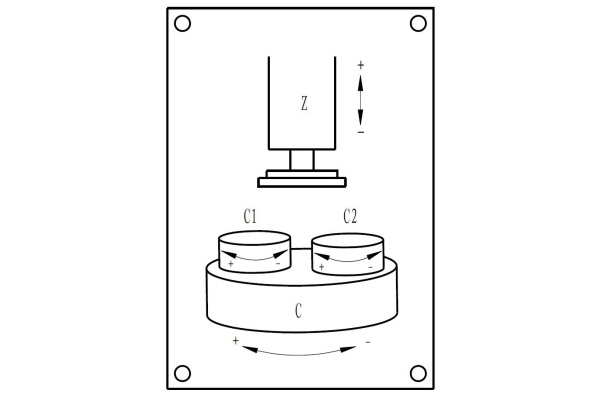

double-station single-sided grinding

Equipment Highlights

Equipment Highlights

● This machine adopts box base, large column, feeding seat and other castings, which has the advantages of good vibration absorption and high rigidity.

● Z-axis feed adopts servo motor screw guide way.

● The feeding parts of this machine adopt swing feeding and disc double-layer feeding seat with high rigidity. The feeding structure adopts hollow sleeve bearing system, each station disc can be driven to rotate separately by servo motor, and the feeding turntable is driven by servo motor, which can realize taking and discharging while processing.

● The workpiece disc C1 is a vacuum chuck, and the workpiece disc C2 is a magnetic chuck. The C1 vacuum chuck provides a complete vacuum system including a vacuum pump, and is equipped with a vacuum pressure gauge to display the pressure of the vacuum chuck and monitor the negative pressure in real time to prevent underpressure from falling off. The function of the system is perfect and reasonable, which can realize the effect of long-term vacuum adsorption of parts. C2 magnetic chuck can absorb ferromagnetic parts with flat bottom surface, which can greatly improve work efficiency in the process of mass grinding.

Technical parameters

Technical parameters

|

Item/Product Model |

Unit |

YHMM7418B |

|

Machining workpiece diameter |

mm |

≤ Φ250 |

|

Machined workpiece thickness |

mm |

10-50 |

|

Grinding wheel size |

mm |

Φ250 |

|

Grinding head motor |

kw |

15 |

|

Grinding head speed |

Rmp |

50-4300 |

|

Feed tray motor power |

kw |

1.75 1 x 2 |

|

Whole machine quality |

t |

3.5 (host) |

|

Overall dimensions of machine tool (length x width x height (LxWxH) |

mm |

20200 x1100x2700 (host) |

Previous article

Previous article

recommend products