YH2M8432F vertical double-sided polishing machine

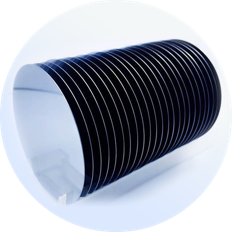

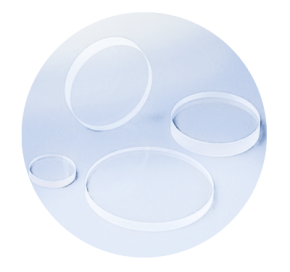

This machine is mainly used for silicon, germanium, quartz crystal and other semiconductor materials and optical glass, ceramics and other non-metallic hard brittle materials made of thin parts of the double-sided grinding and polishing.

Keywords

Precision grinding, intelligent manufacturing technology, integrated solutions

Classification

Typical Machining Parts

Typical Machining Parts

|

|

|

|

|

| silicon wafer | quartz stone glass | optical glass | Ceramics |

Equipment Highlights

Equipment Highlights

1. The pallet, lower disc and hollow shaft of this machine are carried by bearings and fixed sleeves with high rigidity and high precision, which can ensure extremely high pallet end jump. The fixed sleeve and hollow shaft adopt internal and external hole grinding process.

2 Ring gear lifting form: the new research and development of the outer ring gear lifting mechanism, lifting accuracy is higher, consistency is good, lifting no jam phenomenon occurs, the star wheel movement accuracy is higher, the replacement of polishing pad is more convenient.

3 Star wheel meshing form: The newly designed pin meshing, when the inner ring gear or sun gear tooth profile is worn, a single pin can be quickly removed and replaced, without replacing the entire inner ring gear or sun gear, low cost and more convenient maintenance.

4 In order to realize the automatic loading and unloading function of the subsequent industrial robot, the sun gear component and the lower disk drive component of the machine are controlled by servo motor, and the conical positioning pin of the outer ring gear is accurately positioned with the up and down movement of the cylinder in the outer ring gear positioning device, as well as the secondary accurate positioning after rotation, and finally the industrial robot is equipped with the star wheel and the workpiece to run without failure.

5 The liquid supply device ① of this machine adopts independent liquid supply pump and stirring pump to ensure that the grinding liquid is fully suspended and does not precipitate. The liquid supply pipe fittings are all made of stainless steel. The pipe is made of steel wire hose, which is not easy to bend. The liquid flow tank adopts head structure design. Up to 40 liquid discharge pipes are connected to the liquid discharge holes of the upper disc to ensure uniform liquid discharge and large flow of the grinding liquid; ② The liquid supply device (polishing liquid storage barrel) has cooling function. Users can choose to connect cooling water (nozzle specification inner diameter: Φ12) according to their needs. The cooling water temperature is ≤ 15 ℃ and the pressure is 2Kg/cm2.

Technical parameters

Technical parameters

|

Project |

Model |

|

Size of polishing disc |

Φ1070xΦ495x45mm |

|

Upper grinding disc speed |

2-25r/min |

|

Lower grinding disc speed |

2-50r/min |

|

Sun wheel speed |

2-22r/min |

|

Upper plate lifting stroke |

450mm |

|

Lifting stroke of ring gear |

30mm |

|

Maximum processing pressure |

350Kg |

|

End face runout tolerance of lower plate |

0.12mm |

|

Tolerance of ring gear radial runout |

0.25mm |

|

Tolerance of end face runout of ring gear |

0.25mm |

|

Sun gear radial runout tolerance |

0.15mm |

|

Sun gear end face runout tolerance |

0.15mm |

|

Power |

Three-phase five-wire AC380V |

|

Total power of equipment |

15KW |

|

Host size (length × width × height) |

About 1800 × 1500 × 2900mm |

|

Weight of whole machine |

About 3500Kg |

Previous article

Next article

Previous article

Next article

recommend products