YHDM580H high-precision vertical Double Disc grinding machine

Suitable for all kinds of shaped and round metal, non-metallic thin parts (such as bearings, valve plates, aluminum alloy plates, seals, oil pump blades, piston rings, etc.) on the two parallel end face for strong and efficient precision grinding.

Keywords

Precision grinding, intelligent manufacturing technology, integrated solutions

Classification

Typical Machining Parts

Typical Machining Parts

|

|

|

|

| Rotor | silicon carbide plate | Gear |

Processing mode

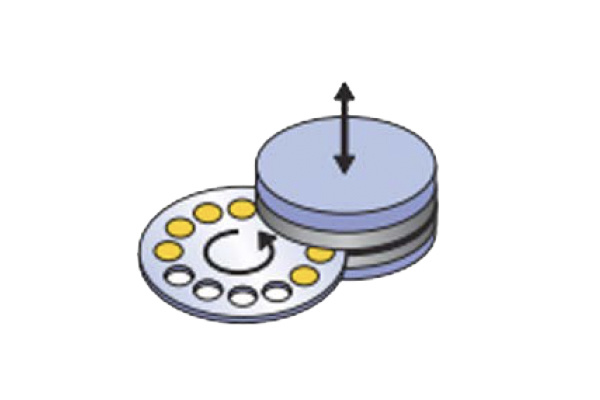

| Type C grinding Suitable for high efficiency, multi-specification variety processing |

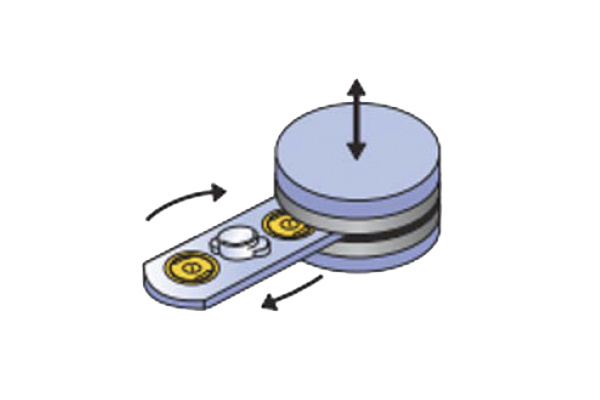

Planetary Grinding (XX) Suitable for thick workpieces, large removal |

|

|

Equipment Highlights

Equipment Highlights

● C- type grinding (optional swing grinding, double-station planetary grinding), high-precision and high-efficiency grinding of both ends of the workpiece;

● The feeding table adopts a fixed method and can be equipped with an automatic loading and unloading device to avoid frequent adjustment due to frequent opening and closing of the feeding table.

● Siemens CNC system (optional central China system), customized HMI human-machine interface, simple operation, powerful and perfect.

The vertical arrangement of the box body adopts the angle adjustment mode of the upper box body, and the angle stability of the grinding head is high;.

● Adopt a new type of dressing mechanism, fixed dressing structure at the entrance, spherical adjustment support structure, sand tile type dressing mechanism, high dressing efficiency.

● Using double nut large diameter ball screw worm gear servo motor drive structure, can realize the upper and lower grinding head micron feed, feed high stability;

● The rear door out of the grinding wheel is adopted, and the special disassembly grinding wheel device is configured;

Technical parameters

Technical parameters

|

Project |

Unit |

YHDM580H |

| Grinding wheel |

mm |

Φ585x75mm * Φ195mm |

| Outside diameter of workpiece |

mm |

Φ10-Φ120 |

| Thickness of machined parts |

mm |

0.8-40 |

| Maximum speed of grinding head | r/min |

100~890, stepless speed regulation |

| Grinding head spindle power | kw |

2x 22kw |

| Feeding speed | r/min |

0.5-10, stepless speed regulation |

| Total mass of machine tool |

kg |

9000 |

| Overall dimension of host |

mm |

4000x3500x2700mm (Water tank and electrical cabinet are placed side by side) |

recommend products