YHJMKG5230 CNC fixed beam gantry guide rail grinder

Large margin grinding and high precision grinding of medium and large plane and guide surface in industrial mother machine, machine tool manufacturing, industrial measuring tools, transportation, aerospace, military and other fields.

Keywords

Precision grinding, intelligent manufacturing technology, integrated solutions

Classification

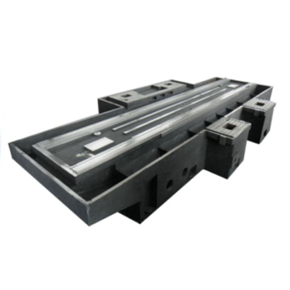

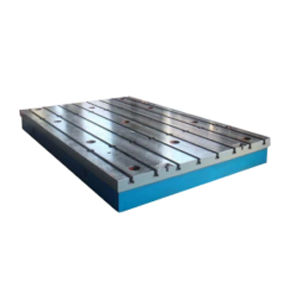

Typical Machining Parts

Typical Machining Parts

|

|

|

|

| industrial mother machine | machine tool manufacturing | Industrial measuring tools |

Equipment Highlights

Equipment Highlights

Double columns and stepped beams form a high-rigidity gantry frame structure. The bed adopts a flat and a V-shaped hydrostatic guide rail. The worktable is controlled by two single-acting oil cylinders to move longitudinally along the bed guide rail. An independent hydraulic station is adopted. Stepless speed regulation, low friction and low noise, and smooth movement. A set of horizontal grinding heads and vertical universal grinding heads are equipped. The grinding heads move horizontally and vertically by servo motors to drive screw screws, and vertically by grating ruler positioning, to achieve horizontal pitch grinding, intermittent feed, micro feed, stepless speed regulation and other functions.

Technical parameters

Technical parameters

|

Maximum grinding workpiece size (length * width * height) |

6100*3000*1000(mm) |

|

Max. grinding workpiece weight |

20000Kg |

|

Longitudinal (X-axis) effective stroke of the table |

6100 |

|

Vertical (Z, Z1 axis) moving distance of grinding head |

1000 |

|

Gantry Spacing |

3300 |

|

Horizontal grinding head grinding wheel spindle speed |

1500 rpm |

|

Horizontal grinding head spindle motor power |

22 Kw |

|

Grinding wheel spindle speed (stepless speed regulation) |

800-2500 rpm |

|

Vertical universal grinding head spindle motor power |

16 Kw |

|

Rotary angle of vertical universal grinding head |

± 90 °, minimum dividing value: 1 ° |

|

Table longitudinal movement (X-axis) speed |

5-25 m/min |

|

Grinding head vertical feed (Z, Z1 axis) rapid feed speed |

4 m/min |

|

Grinding head vertical feed (Z1 axis) continuous feed speed |

0-2500 mm/min |

|

Minimum feed of grinding head vertical feed (Z, Z1 axis) |

0.001mm |

|

Rapid feed speed of grinding head transverse feed (Y, Y1 axis) |

8 m/min |

|

Minimum feed of grinding head transverse feed (Y, Y1 axis) |

0.001mm |

|

Straightness and flatness of machined workpiece |

0.005/1000 mm,0.01/1000×1000 mm |

Previous article

Previous article

recommend products