YHM7430 high-precision vertical single-side grinding machine

This machine is an automatic and high-efficiency machine tool, which is suitable for batch processing parts. It is mainly used for single-sided grinding of parts. CBN grinding wheel and diamond grinding wheel are used for high-efficiency precision single-sided grinding and thinning of sapphire, glass, ceramics, semiconductors and other metal and non-metal hard and brittle materials. Can be widely used in single-sided grinding and thinning of LED sapphire substrates, semiconductors and other products.

Keywords

Precision grinding, intelligent manufacturing technology, integrated solutions

Classification

Typical Machining Parts

Typical Machining Parts

|

|

|

|

|

||||||||||

| Sapphire | Glass | Ceramics | silicon wafer | ||||||||||

Processing mode

Equipment Highlights

Equipment Highlights

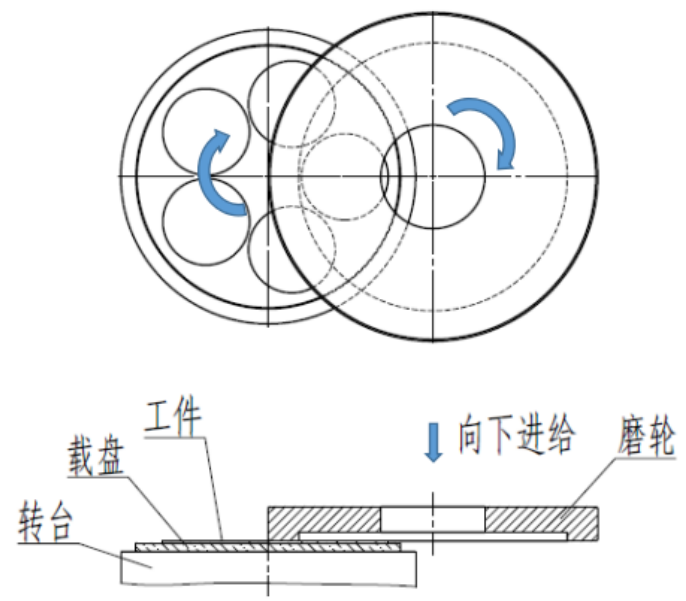

1. This machine adopts IN-FEED feed grinding theory. The servo motor drives the grinding wheel to move in the vertical direction. The lower disc is driven by servo and synchronous belt. It can rotate in the same direction or opposite direction with the grinding wheel according to the requirements of the process.

2. The machine adopts precision cross roller bearing deep groove ball bearing to support the workpiece spindle, with high rigidity and precision. Vacuum adsorption is used to clamp the tooling or workpiece.

3. The grinding head uses an electric spindle to drive the grinding wheel to rotate, and uses a classic screw wire servo motor to drive the vertical feed; the Z axis uses high-precision grating closed-loop feedback to control the Z axis feed accuracy.

4, the use of dual-head measuring instrument Marpos D-Model 2Unimar, can achieve precision control of workpiece grinding thickness size error.

5. Adopt interactive man-machine interface (touch screen), precise control and simple use.

Technical parameters

Technical parameters

|

Project |

Parameters |

|

|

Grinding wheel diameter |

Φ380mm |

|

|

Machinable parts |

Maximum outer diameter |

Φ300mm |

|

Electric spindle spindle |

Speed |

100-2500r/min |

|

Power |

11kW |

|

|

Z-axis |

Travel |

125mm |

|

Power |

0.4kW |

|

|

Minimum unit |

0.001mm |

|

|

Fast moving speed |

400mm/min |

|

|

Maximum feed |

5mm/s |

|

|

Minimum resolution |

0.1μm |

|

|

Workbench |

Feed stroke |

400mm |

|

Fast moving speed |

10m/min |

|

|

Speed |

5-350r/min |

|

|

On-line measurement of repeated positioning accuracy |

± 0.5μm |

|

|

On-line thickness measurement resolution |

0.1μm |

|

|

machining accuracy |

TTV Monolithic |

3μm |

|

Between TTV films and films |

± 3μm |

|

|

Weight of whole machine |

3500kg |

|

Previous article

Previous article

recommend products